Homologation Management Services

What is Homologation:

Homologation is the process of bringing a product into compliance with, and/or certified to guidelines established by a regulating authority, generally at a national level. Homologation is typically a prerequisite to distributing or delivering products to a country or region. The term Homologation, which has been used in the automotive industry for some time, can also be applied to regulatory compliance of non-automotive products, components, and systems. Why add terminology that upper management can abuse in an attempt to appear qualified? The reason is there is no better way to describe this niche field. The closest would be “regulatory product compliance” which is simply too long to say on a regular basis and still may not narrow it down enough.

Challenges with Global Homologation:

Manufacturers expanding into global markets, particularly developing markets, are faced with a growing number of regulatory requirements of which safety, EMC, wireless, energy, and environmental disciplines are becoming common. As a result of the increased complexity of global homologation, manufacturers can experience multiple hurdles in attaining and maintaining market access for their products, including:

- In-house staff becoming overburdened by extensive and ever-changing requirements;

- Excessive certification costs from over-certification of models within the same platform;

- Lack of in-house expertise to question legitimacy of certification efforts proposed by inexperienced contract manufacturers or local test laboratories;

- Unexpected expiration of certifications causing lapse in market coverage;

- Loss of employee who was entrusted with company’s entire homologation knowledge.

Navigating global certification processes with an expanding number of compliance disciplines has become a full-time job. Instead of relying on one person within the organization to muddle through this ever-changing maze of compliance, it may make sense to partner with an organization that specializes in product certification services.

Outsourcing Homologation Management:

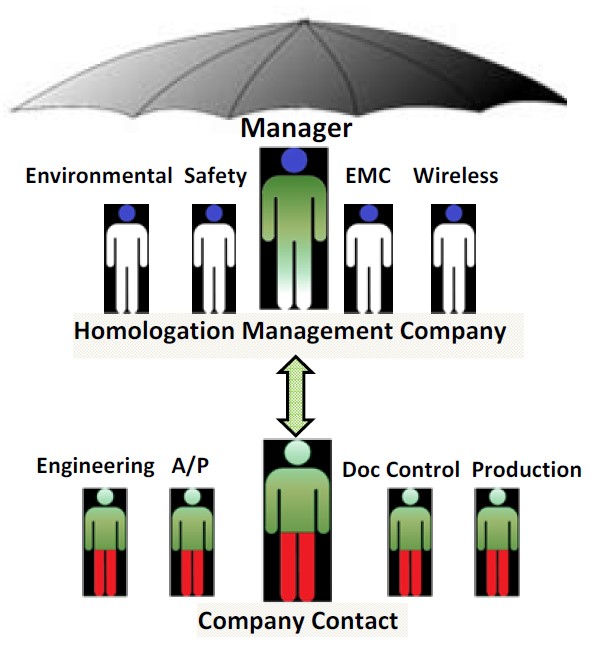

G&M provides a service making use of our technical background, familiarity with global homologation schemes, and experience in working with certification entities. Our overall knowledge bank coupled with our autonomy from any one certification agency or entity, gives us the ability to serve as an ideal homologation management partner. As part of an HMS program, G&M will provide a primary contact to serve as your company’s homologation manager. This person will work as part of your team to manage and streamline compliance related activities. This person will not only rely on their own knowledge and experience to perform this function but will draw from the collective knowledge of the G&M team. This service is similar to certification consulting but designed to be integrated into a company for more seamless results. The following are examples of how an experienced homologation team working as your in-house provider can provide value to your company:

- Development of effective certification programs, maximizing models per certification, and reducing overall costs

- Management of outside vendors, ensuring their certification efforts are efficient, which improves time to market

- Removal of homologation tasks from company staff, allowing them to be more productive

- Tracking certifications with G&M CATS system to avoid unexpected expirations, minimizing loss of market access

- Having an established company manage homologation improves consistency and reduces the possibility of chaos due to employee turnover.

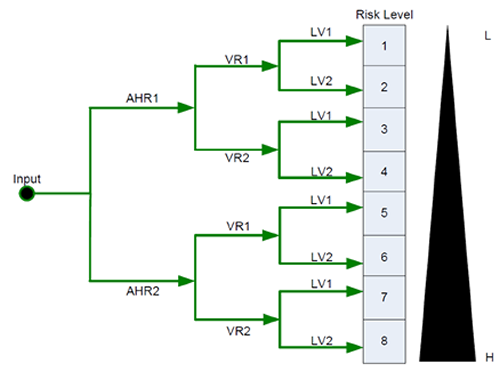

- Assistance in analyzing risk of homologation related business decisions can save both time and money

- A homologation management company that retains a significant group of member customers can leverage that volume with certification bodies to achieve volume pricing (similar to insurance company model), which offsets costs of partnering with a management company.

Outsourcing Vs. Hiring:

The question for many companies is: Can we continue to treat the impact of growing homologation requirements as an adjunct responsibility given to one or more existing employees? If not, can we justify or afford a full-time employee? Before deciding that, are we equipped to identify a competent applicant? If we answered yes to the last two questions; does it make business sense to hire specialized personnel who do not directly contribute to the core competencies of the organization?

G&M’s HMS is the perfect solution for product makers who realize treating homologation as an adjunct responsibility is a losing proposition but can’t justify or don’t want to assume the burden of hiring a full-time employee. See figure below for an illustration of the division of responsibilities made possible by the HMS model: